Laser vuam tshuabyog ib qho zoo thiab meej vuam txoj kev uas siv lub siab-zog-density laser beam raws li lub tshav kub qhov chaw.Laser vuam yog ib qho tseem ceeb ntawm kev siv cov khoom siv laser ua tshuab.Nyob rau xyoo 1970, nws tau siv los ua cov ntaub ntawv nyias nyias thiab vuam qis.Cov txheej txheem vuam yog ntawm thermal conduction hom, uas yog, qhov chaw ntawm lub workpiece yog rhuab los ntawm laser hluav taws xob, thiab cov nplaim hluav taws xob diffuses rau sab hauv los ntawm thermal conduction.Los ntawm kev tswj qhov dav, lub zog, lub zog siab tshaj plaws thiab rov ua dua zaus ntawm lub laser pulse thiab lwm yam tsis ua rau yaj lub workpiece thiab tsim ib lub pas dej ua ke tshwj xeeb.Vim nws qhov tshwj xeeb zoo, nws tau ua tiav zoo siv hauv kev vuam precision ntawm micro thiab me me.

Ib, Vuam yam ntxwv

Nws belongs rau fusion vuam, uas siv lub laser beam raws li lub zog los cuam tshuam rau kev sib koom ua ke ntawm vuam.

Lub laser beam tuaj yeem coj los ntawm lub tiaj tus kho qhov muag, xws li daim iav, thiab tom qab ntawd muab tso rau ntawm lub vuam seam los ntawm lub ntsiab lus tsom lossis daim iav.

Laser vuam yog tsis sib cuag welding, tsis muaj siab yuav tsum tau thaum lub sij hawm ua hauj lwm, tab sis inert roj yuav tsum tau tiv thaiv oxidation ntawm lub pas dej ua ke molten, thiab muab tub lim hlau yog siv qee zaus.

Laser vuam tuaj yeem ua ke nrog MIG welding los tsim laser MIG sib txuas vuam kom ua tiav kev nkag mus rau vuam loj, thiab cov khoom siv hluav taws xob txo qis heev piv rau MIG vuam.

二 、 Ua hauj lwm hauv paus ntsiab lus ntawm pwm vuam tshuab

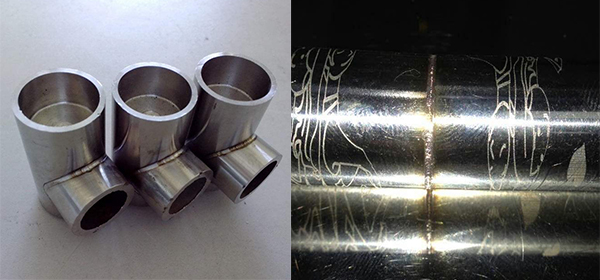

Cov pwm laser vuam tshuab kuj yog ib ceg ntawm covlaser vuam tshuab, yog li lub hauv paus ntsiab lus ntawm kev ua hauj lwm yog siv high-zog laser pulses kom sov cov khoom nyob rau hauv ib cheeb tsam me me.Lub zog ntawm cov hluav taws xob laser diffuses rau hauv cov khoom siv los ntawm kev ua cua sov, thiab cov khoom yog melted thiab tsim.tshwj xeeb lub pas dej ua ke.Nws yog ib yam tshiab ntawm txoj kev vuam, feem ntau yog rau vuam ntawm cov ntaub ntawv nyias-walled thiab precision qhov chaw, thiab muaj peev xwm paub qhov chaw vuam, taub qab vuam, plooj vuam, sealing vuam, thiab lwm yam me me deformation, vuam ceev ceev, du thiab zoo nkauj vuam. seam, tsis xav tau lossis kev kho yooj yim tom qab vuam, siab vuam seam zoo, tsis muaj qhov pores, kev tswj kom meej, me me tsom qhov chaw, siab qhov tseeb, thiab yooj yim automation.High-power laser vuam tshuab tau raug launched, thiab ntau yam ntawm laser vuam tshuab thiab kho yuav tsum tau paub rau cov ntaub ntawv tuab.

Qauv:

三 、 Cov yam ntxwv ntawm pwm laser vuam

Cov pwm laser vuam tshuab txais lub vijtsam loj LCD Suav interface zaub, uas ua rau nws yooj yim rau tus neeg teb xov tooj kawm thiab ua haujlwm.Cov cuab yeej siv kuj siv cov font programming muaj nuj nqi kom paub ntau hom kev ua haujlwm, uas yog tsim rau kev kho pwm ntawm cov ntaub ntawv feem ntau.Tsis tsuas yog lub tshav kub cuam tshuam rau thaj tsam me me, oxidation tus nqi tsawg, tab sis kuj yuav tsis muaj hlwv, pores thiab lwm yam tshwm sim.Tom qab cov pwm raug kho, cov nyhuv ntawm kev kho yog ua kom tsis muaj qhov tsis sib xws ntawm qhov sib koom ua ke, thiab nws yuav tsis ua rau pwm deformation.

四 、 Configuration thiab processing technology

1. Cov pwmlaser vuam tshuabyuav tsum siv 10X lossis 15X microscope los saib xyuas kev ua haujlwm.

2. Lub zog ntawm cov pwm laser vuam tshuab tuaj yeem txais yuav lub waveform adjustable muaj nuj nqi, uas yog tsim rau vuam ntawm cov khoom sib txawv.Xws li: tuag steel, stainless hlau, beryllium tooj liab, txhuas, thiab lwm yam.

3. Lub kaw lus CCD (lub koob yees duab system) tuaj yeem siv rau kev saib xyuas, kev ua haujlwm yog: ntxiv rau tus neeg teb xov tooj saib los ntawm lub tshuab tsom, cov neeg ua haujlwm tsis tuaj yeem saib tag nrho cov txheej txheem vuam los ntawm kev tshuaj ntsuam ntawm lub koob yees duab system, cov cuab yeej no yog muaj txiaj ntsig zoo rau kev tsis ua haujlwm Cov kev cob qhia ntawm cov neeg ua haujlwm thiab kev ua yeeb yam ua yeeb yam tau ua lub luag haujlwm zoo hauv kev txhawb nqa lub tshuab laser vuam.

4. Nws tuaj yeem yaj vuam hlau ntawm cov kab sib txawv, ntawm 0.2 txog 0.8 inch.

5. Cov pwm laser vuam tshuab yuav tsum muaj kev tiv thaiv los ntawm cov roj argon, thiab cov kev pab cuam yuav tsum tau teem rau emit argon roj ua ntej thiab tom qab ntawd lub laser los tiv thaiv oxidation ntawm thawj pulsed laser thaum ua tas mus li.

6. Thaum cov pwm yog laser welded, feem ntau tshwm sim yog tias muaj cov cim tom ib ncig ntawm qhov vuam.Nws yog ib qho tsim nyog yuav tsum siv txoj kev ntawm laser cua xuas nrig ntaus los npog cov kev hloov pauv uas yuav ua rau cov cim tom los tiv thaiv qhov tshwm sim ntawm cov cim tom.Nws yog qhov txaus tias qhov chaw teeb pom kev zoo tshaj qhov ntug ntawm txoj haujlwm vuam los ntawm 0.1mm.

Post lub sij hawm: Jun-12-2023