Laser vuam yog cov txheej txheem vuam siv los koom nrog ntau daim hlau los ntawm kev siv lub tshuab laser.Lub laser vuam system muab cov ntsiab lus kub qhov chaw, tso cai rau nqaim, sib sib zog nqus welds thiab siab vuam tus nqi.Cov txheej txheem no yog siv ntau zaus hauv kev siv vuam ntim siab, xws li hauv Automotive Industry.

Laser vuam ceev cov txheej txheem ntawm kev hloov cov khoom forged nrog stamped qhov chaw.Laser welding yog siv los hloov discrete qhov chaw welds nrog tas li laser welds, uas tuaj yeem txo qhov sib tshooj dav thiab qee qhov ntxiv dag zog, thiab tuaj yeem ua kom lub ntim ntawm lub cev qauv nws tus kheej.Yog li ntawd, qhov hnyav ntawm lub tsheb lub cev tuaj yeem raug txo los ntawm 56kg.Daim ntawv thov ntawm laser vuam tau ua tiav qhov hnyav txo thiab emission txo, uas ua tau raws li cov kev cai ntawm kev tiv thaiv ib puag ncig niaj hnub no.

Laser vuam yog siv rau tailor welding ntawm tsis sib npaug thickness daim hlau, thiab cov txiaj ntsig tseem ceeb dua.Lub tshuab no hloov cov txheej txheem tsim khoom ib txwm ua-thawj stamping rau hauv qhov chaw, thiab tom qab ntawd pom cov vuam mus rau hauv ib qho tag nrho-rau hauv: thawj vuam ntau qhov sib txawv nrog cov thicknesses sib txawv rau hauv tag nrho, thiab tom qab ntawd stamping thiab sib sau, txo cov naj npawb ntawm cov khoom thiab siv ntau cov ntaub ntawv.Tsim nyog, cov qauv thiab kev ua haujlwm tau zoo dua qub.

Kev sib txawv laser vuam txoj kev feem ntau yog siv rau vuam ntawm lub cev sib txawv.Cov hauv qab no yog cov npe ntawm ntau txoj kev siv laser vuam feem ntau siv hauv kev lag luam tsheb.

(1) Laser brazing

Laser brazing feem ntau yog siv rau kev sib txuas ntawm lub hau saum toj kawg nkaus thiab sab phab ntsa, lub hau npog, thiab lwm yam. Volkswagen, Audi, Peugeot, Ford, Fiat, Cadillac, thiab lwm yam, txhua tus siv txoj kev vuam no.

(2) Laser self-fusion vuam

Laser self-fusion vuam belongs rau kev sib sib zog nqus welding, uas yog tsuas yog siv rau lub ru tsev thiab sab panels, tsheb qhov rooj, thiab lwm yam. Tam sim no, ntau hom tsheb ntawm Volkswagen, Ford, GM, Volvo thiab lwm yam manufacturers siv laser self-fusion vuam.

(3) Laser tej thaj chaw deb vuam

Laser tej thaj chaw deb welding siv neeg hlau + galvanometer, tej thaj chaw deb beam positioning + vuam, thiab nws qhov kom zoo dua nyob rau hauv heev shortening lub sij hawm positioning thiab ntau dua efficiency piv nrog ib txwm laser ua.

Laser vuam kuj tseem siv tau rau cigar sib zog, valve lifters, lub tog raj kheej gaskets, roj injectors, txim plugs, zog, sab ncej, tsav shafts, radiators, clutches, cav tso kav, supercharger qag, thiab airbag liner kho thiab splicing ntawm lub tsheb puas. ntu.

Laser welding muaj ntau qhov zoo thiab cov txiaj ntsig zoo tshaj li cov txheej txheem vuam ib txwm muaj thiab tuaj yeem txo tus nqi zoo thaum txhim kho kev tsim khoom thiab zoo.

Laser vuam muaj cov yam ntxwv hauv qab no:

① Cov cua kub qis (ntsuas).

② Qhov chaw ua haujlwm thiab txoj haujlwm yog tswj tau meej.

③ Lub tshav kub cuam tshuam yog me me.

④ Lub vuam deformation yog me me, thiab tsis tas yuav tsum tau kho tom qab vuam.

⑤ Kev ua haujlwm tsis sib cuag, tsis tas yuav tsum tau nias lub tshuab ua haujlwm thiab kho qhov chaw.

⑥Nws tuaj yeem paub qhov vuam ntawm cov khoom sib txawv.

⑦ Lub vuam ceev yog ceev.

⑧ Tsis muaj thermal cuam tshuam, tsis muaj suab nrov thiab tsis muaj kuab paug rau lub ntiaj teb sab nraud.

Cov tshuab pom zoo tsim nyog rau vuam pib yog raws li hauv qab no:

Laser vuam tshuab rau Pwm

Nrog rau txoj kev loj hlob ntawm kev lag luam, laser vuam tshuab yog lossi tshawb fawb thiab innovated.Tam sim no, nyob rau hauv kev lag luam welding, nrov laser vuam tshuab yog vim nws cov yam ntxwv zoo heev thiab qhia tau hais tias cov txheej txheem zoo thaum lub sij hawm vuam txheej txheem.Yog li nws tuaj yeem siv dav hauv ntau qhov chaw.

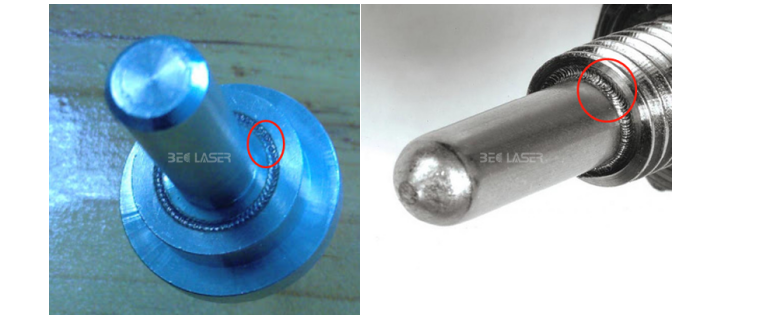

Cov pwm hauv pwm laser vuam ua lub luag haujlwm tseem ceeb hauv kev lag luam niaj hnub no, thiab nws qhov zoo ncaj qha txiav txim siab qhov zoo ntawm cov khoom.Kev txhim kho lub neej kev pab cuam thiab qhov tseeb ntawm cov pwm thiab ua kom lub voj voog tsim pwm yog cov teeb meem kev lag luam uas ntau lub tuam txhab yuav tsum tau daws sai.Txawm li cas los xij, kev ua haujlwm tsis zoo xws li kev sib tsoo, deformation, hnav, thiab txawm tias tawg feem ntau tshwm sim thaum siv pwm.Yog li ntawd, laser vuam kho tshuab kuj tseem tsim nyog rau kev kho pwm.

Laser vuam tshuab yog ib hom tshiab vuam txoj kev, feem ntau yog rau vuam ntawm nyias-walled cov ntaub ntawv thiab precision qhov chaw.Nws tuaj yeem paub qhov chaw vuam, taub qab vuam, plooj vuam, sib khi vuam, thiab lwm yam, nrog rau qhov sib piv siab, qhov dav me me vuam, thiab thaj chaw muaj kev kub ntxhov.Me me, me me deformation, ceev vuam ceev, du thiab zoo nkauj vuam seam, tsis xav tau los yog yooj yim ua tom qab vuam, siab vuam seam zoo, tsis muaj cua qhov, meej tswj, me me tsom qhov chaw, siab positioning raug, thiab yooj yim kom paub automation.

Ib qho piv txwv ntawm daim ntawv thov ntawm laser vuam hauv kev lag luam pwm yog pwm kho laser vuam tshuab.Cov cuab yeej no yooj yim rau cov neeg siv khoom siv, tuaj yeem ua kom nrawm nrawm ntawm kev kho vuam, thiab kev kho cov nyhuv thiab qhov tseeb yog nyob ze rau qhov zoo nkauj, uas ua rau cov cuab yeej siv dav hauv kev lag luam pwm vuam.Kev kho cov vuam kub cuam tshuam rau thaj tsam ntawm lub tshuab vuam no me me, thiab nws tsis tas yuav tsum tau ua kom sov ua ntej, thiab cov welded workpiece tsis tshwm sim annealing tshwm sim tom qab ua haujlwm.Qhov no laser vuam kho tshuab tsis tsuas yog siv los kho pwm hnav, tab sis kuj tuaj yeem ua tiav qhov vuam ntawm lub cev sib txawv.

Post lub sij hawm: Lub Xya hli ntuj-15-2021