Tam sim no,laser vuam tshuabtau dav siv nyob rau hauv advertising kho kom zoo nkauj, hniav nyiaj hniav kub, qhov rooj thiab qhov rais thiab lwm yam lag luam.Dab tsi yog qhov txawv ntawm laser welding thiab argon arc vuam, soldering thiab lwm yam welding technologies?Dab tsi ua qhovlaser vuam tshuabvam tias yuav maj mam dhau los ua lub ntsiab ntawm cov cuab yeej vuam tam sim no?

Laser vuam tshuabyog ib yam tshiab ntawm txoj kev vuam, feem ntau yog siv rau vuam ntawm nyias-walled cov ntaub ntawv thiab cov khoom zoo, uas tuaj yeem ua tiav qhov chaw vuam, taub qab vuam, plooj vuam, sealing vuam, thiab lwm yam. Me me, me me deformation, vuam ceev ceev, tiaj tus thiab lwm yam. zoo nkauj vuam seam, tsis xav tau los yog tsuas yog kev kho yooj yim tom qab vuam, siab vuam seam zoo, tsis muaj pores, tswj kom raug, me me teeb pom kev zoo, siab positioning raug, yooj yim ua kom tiav automation.Nws siv high-zog laser pulses los ua kom sov cov khoom hauv ib cheeb tsam me me.Lub zog ntawm lub laser hluav taws xob diffuses mus rau hauv cov khoom los ntawm tshav kub conduction, melts cov khoom los tsim ib tug tshwj xeeb molten pas dej ua ke, thiab ces dissolves ob cov ntaub ntawv nyob rau hauv kev sib cuag ua ke.

Yuav ua li cas laser vuam ua haujlwm

Laser vuam yog irradiate ib tug high-siv laser beam rau cov hlau nto, thiab los ntawm kev sib cuam tshuam ntawm lub laser thiab hlau, cov hlau yog melted los ua ib tug weld.Hlau melting tsuas yog ib qho ntawm lub cev tshwm sim thaum muaj kev cuam tshuam ntawm laser nrog hlau.Qee lub sij hawm lub teeb lub zog tsis yog tsuas yog hloov mus rau hauv cov hlau melting, tab sis tshwm sim nyob rau hauv lwm yam ntaub ntawv, xws li vaporization, plasma tsim, thiab lwm yam. Txawm li cas los xij, kom ua tau zoo fusion vuam, hlau melting yuav tsum yog daim ntawv tseem ceeb ntawm lub zog hloov dua siab tshiab.Txog rau qhov kawg no, nws yog ib qho tsim nyog yuav tsum nkag siab txog ntau yam tshwm sim ntawm lub cev tsim tawm hauv kev sib cuam tshuam ntawm laser thiab hlau thiab kev sib raug zoo ntawm cov phenomena lub cev thiab laser tsis, yog li ntawd feem ntau ntawm lub zog laser tuaj yeem tswj tau los ntawm kev tswj cov laser tsis.

Nws yog hloov dua siab tshiab rau hauv lub zog ntawm cov hlau melting kom ua tiav lub hom phiaj ntawm vuam.

Cov txheej txheem tsis ntawm laser vuam

1. Lub zog ceev

Lub zog ceev yog ib qho tseem ceeb tshaj plaws hauv kev ua laser.Nrog lub zog hluav taws xob ntau dua, txheej saum npoo av tuaj yeem ua kom sov rau cov boiling taw tes hauv cov microrizing ntau, ua rau muaj ntau ntawm vaporization.Yog li ntawd, lub zog ceev ceev yog qhov zoo rau cov txheej txheem tshem tawm xws li xuas nrig ntaus, txiav, thiab kos duab.Rau qis zog ceev, nws yuav siv sij hawm ob peb milliseconds rau saum npoo kub kom ncav cuag lub boiling point.Ua ntej qhov chaw vaporizes, txheej hauv qab mus txog qhov melting point, uas yog ib qho yooj yim los tsim ib tug zoo fusion weld.Yog li ntawd, nyob rau hauv conduction laser vuam, lub hwj chim ceev yog nyob rau hauv ntau ntawm 104 ~ 106W / cm2.

2. Laser pulse waveform

Laser pulse puab yog ib qho teeb meem tseem ceeb hauv laser vuam, tshwj xeeb tshaj yog rau nyias daim ntawv vuam.Thaum lub siab siv lub laser beam hits saum npoo ntawm cov khoom, 60 ~ 98% ntawm lub zog laser yuav tshwm sim thiab ploj ntawm cov hlau nto, thiab qhov kev xav txawv ntawm qhov kub thiab txias.Thaum lub sijhawm ua haujlwm ntawm lub laser mem tes, qhov cuam tshuam ntawm cov hlau sib txawv heev.

3. Laser mem tes dav

Pulse dav yog ib qho tseem ceeb ntawm cov mem tes laser vuam.Nws tsis yog tsuas yog ib qho tseem ceeb tsis sib txawv ntawm cov khoom tshem tawm thiab cov khoom siv melting, tab sis kuj yog ib qho tseem ceeb parameter uas txiav txim siab tus nqi thiab ntim ntawm cov khoom siv.

4. Kev cuam tshuam ntawm defocus tus nqi ntawm vuam zoo

Laser vuam feem ntau yuav tsum tau muaj qee yam defocusing txoj kev, vim hais tias lub hwj chim ceev nyob rau hauv nruab nrab ntawm qhov chaw ntawm lub laser tsom yog siab dhau lawm, thiab nws yog ib qho yooj yim mus evaporate rau hauv ib lub qhov.Lub zog hluav taws xob kev faib tawm yog cov khoom sib txawv thoob plaws hauv cov dav hlau kom deb ntawm lub Laser tsom.

Muaj ob txoj kev defocusing: zoo defocusing thiab tsis zoo defocusing.Lub dav hlau focal saum lub workpiece yog qhov zoo defocus, txwv tsis pub nws yog qhov tsis zoo defocus.Raws li txoj kev xav geometrical optics, thaum lub defocus yog qhov zoo, lub zog ceev ntawm lub dav hlau sib txuas yog kwv yees li qub, tab sis cov duab ntawm lub pas dej molten tau sib txawv.Thaum lub defocus yog qhov tsis zoo, qhov tob tob tob tuaj yeem tau txais, uas muaj feem xyuam rau cov txheej txheem tsim ntawm lub pas dej molten.Cov kev sim qhia tau hais tias thaum lub laser yog rhuab rau 50 ~ 200us, cov khoom pib yaj, tsim cov kua theem hlau thiab vaporizing, ua lag luam-siab zog chav, uas yog ejected ntawm ib tug heev ceev ceev, emitting ib dazzling dawb lub teeb.Nyob rau tib lub sijhawm, lub siab concentration ntawm vapor txav cov kua hlau mus rau ntawm ntug ntawm lub pas dej molten, tsim kev nyuaj siab nyob rau hauv nruab nrab ntawm lub pas dej molten.Thaum lub defocus tsis zoo, lub zog sab hauv ntawm cov khoom yog siab dua li ntawm qhov chaw, thiab nws yog ib qho yooj yim los tsim kom muaj zog melting thiab vaporization, thiaj li hais tias lub teeb lub zog yuav kis mus tob rau hauv cov khoom.Yog li ntawd, nyob rau hauv kev siv tswv yim, thaum qhov tob tob yuav tsum tau loj, tsis zoo defocusing yog siv;Thaum welding nyias cov ntaub ntawv, zoo defocusing yuav tsum tau siv.

Piv nrog cov tsoos vuam tshuab,laser vuam tshuabmuaj qhov zoo hauv qab no

1. Nws muaj ntau yam ua tiav, thiab vuam seam me me, uas tuaj yeem paub qhov tseeb vuam;

2. Cov qauv tsim yog cov neeg siv-phooj ywg, lub taub hau laser tuaj yeem ncab rov qab, sab laug thiab sab xis, nce thiab nqis manually, haum rau kev tsis sib cuag thiab kev sib cuag ntev ntawm ntau yam khoom;

3. Lub vuam seam yog du, cov qauv vuam zoo ib yam, tsis muaj qhov hws, tsis muaj kuab paug, thiab ob peb qhov tsis xws luag;

4. Lub vuam ceev ceev, qhov sib piv yog loj, qhov deformation yog me me, thiab qhov kev ua tau zoo yog ruaj khov, uas tuaj yeem paub tsis siv neeg ntau lawm;

4.Nws yog ib yam tshiab ntawm txoj kev vuam.Laser welding feem ntau yog tsom rau kev vuam ntawm cov ntaub ntawv nyias-walled thiab precision qhov chaw.Nws tuaj yeem paub qhov chaw vuam, pob tw vuam, plooj vuam, vuam vuam, thiab lwm yam. Cov cheeb tsam me me, me me deformation, vuam ceev ceev, du thiab zoo nkauj vuam seam, tsis xav tau lossis kev kho yooj yim tom qab vuam, siab vuam seam zoo, tsis muaj pores, Kev tswj xyuas meej, me me tsom qhov chaw, qhov chaw siab qhov tseeb, yooj yim rau kev ua tiav Automation, yog li nws tau nyiam los ntawm cov neeg siv, tsis tsuas yog txhim kho kev tsim khoom thiab kev ua haujlwm, tab sis kuj txo cov kev ua haujlwm tom qab cumbersome tom qab ua haujlwm.

Laser vuam kev lag luam

Kev lag luam tsheb, kev lag luam pwm, kev lag luam kho mob, kev lag luam hniav nyiaj hniav kub, thiab lwm yam kev lag luam sib txawv xav tau cov tshuab laser sib txawv.

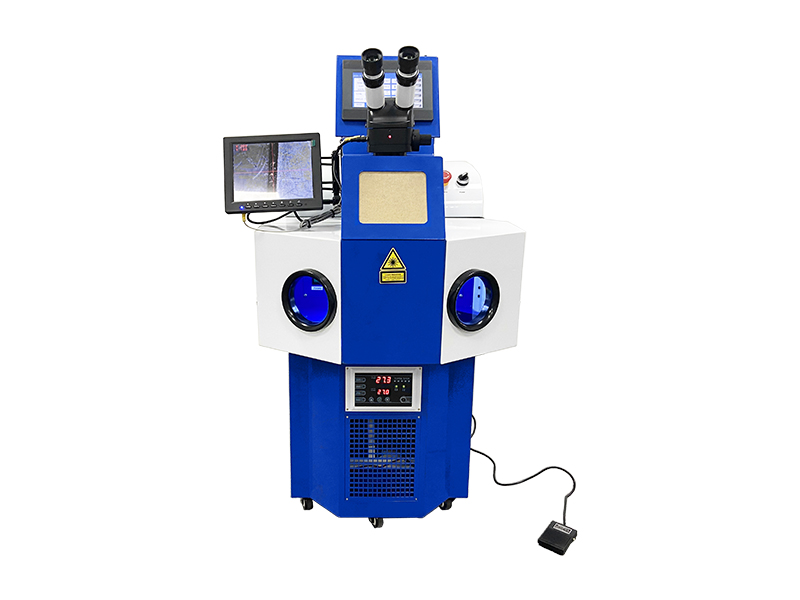

Hom ntawmlaser vuam tshuab

1.Fiber laser vuam tshuab-Handheld hom

2.Mould laser vuam tshuab- phau ntawv hom

3.Cantilever laser vuam tshuab-Nrog tub sab caj npab

4.3-Axis laser vuam tshuab-Tsis siv neeg hom

5.Jewelry laser vuam tshuab-Desktop Hom

6.Jewelry laser vuam tshuab-Inbuilt Dej Chiller

7.Jewelry laser vuam tshuab-Separate Dej Chiller

Qauv:

Post lub sij hawm: Apr-27-2023