Pwm Laser Vuam Tshuab-Kev Taw Qhia Hom

Khoom Taw Qhia

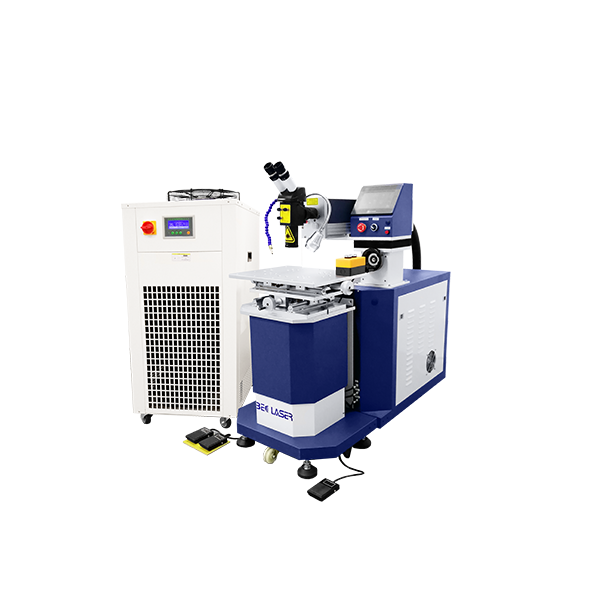

Niaj hnub no lub precision vuam cov khw tshwj xeeb hauv cov yas txhaj tshuaj pwm, tuag thiab kho cov cuab yeej muaj ntau yam tshiab technologies muaj los txhim kho lawv lub peev xwm los muab cov qib siab tshaj plaws ntawm kev ua haujlwm zoo, kev ua haujlwm zoo, thiab kev pabcuam rau lawv cov neeg siv khoom.Ib qho ntawm cov thev naus laus zis loj tshaj plaws yog kev siv phau ntawv laser vuam tshuab ua lwm txoj hauv kev siv tshuab tsom iav GTA vuam.

Ib qho ntawm cov ntsiab lus tseem ceeb hauv kev ua phau ntawv laser vuam siv tau rau Cov Cuab Yeej thiab Tuag lossis Pwm tsim thiab kho yog kev txhim kho ntawm lub tswv yim "dawb-tsav".Nyob rau hauv no txoj kev, lub laser generates ib tug nyob twj ywm infrared lub teeb mem tes uas yog tsom los ntawm lub microscope tus ntoo khaub lig-cov plaub hau.Lub laser mem tes tuaj yeem tswj tau qhov loj thiab siv.

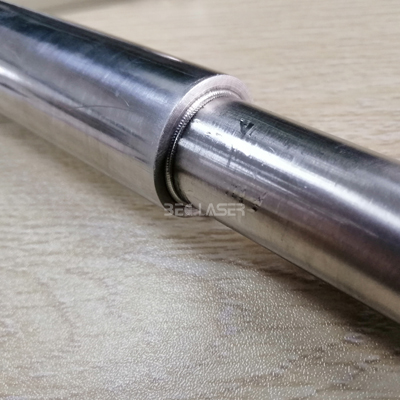

Laser vuam yog qhov zoo tagnrho rau kev hloov kho thiab kho cov pwm, cov cuab yeej thiab tuag txawm tias vim kev puas tsuaj, hnav thiab tsim kua muag, lossis kev hloov pauv hauv kev tsim cov khoom ua haujlwm.Cov txheej txheem yog ceev, meej thiab yuav tsis ua puas qhov chaw nyob ib puag ncig.

Tib neeg tsim raws li ergonomics ua rau lub tshuab meej, zoo-zoo, kev ua haujlwm ruaj khov, thiab lub neej ntev, tsim nyog rau precision pwm kho.Nws yog cov cuab yeej siv vuam zoo nrog lub zog siab kub ntawm lub zog ntawm laser, uas ua haujlwm zoo ntawm cov vuam thiab kho qee qhov me me ntawm cov pwm, xws li: tawg, hlwv, chipping, pwm flashing, sealing npoo, thiab lwm yam. pwm.Nws yog txhim kho los ntawm kev qhia txog kev siv tshuab German siab heev.

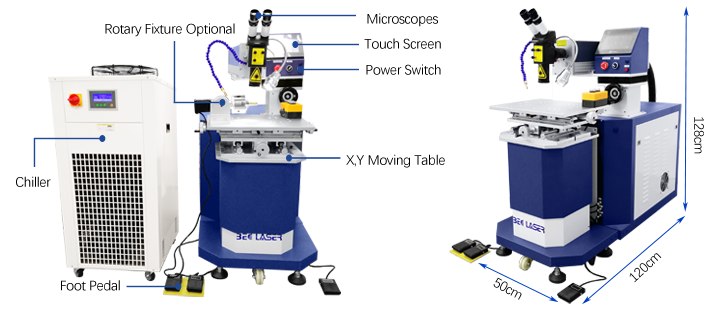

Nta

1. Ceramic converging kab noj hniav yog corrosion resistant thiab kub resistant, thiab muaj 8-10 xyoo kev pab cuam lub neej.Lub neej ntawm xenon teeb yog ntau tshaj 8 lab lub sij hawm.

2. Siv lub teeb pom kev zoo tshaj plaws tiv thaiv kev tiv thaiv kom tshem tawm qhov khaus ntawm qhov muag los ntawm lub teeb thaum ua haujlwm.

3. Kov npo vaj huam sib luag los kho qhov tsis muaj, uas yooj yim thiab yooj yim.

4. Lub rooj zaum ua haujlwm tuaj yeem nqa tau, thiab txav mus rau peb qhov loj me.

5. Qhov loj ntawm lub teeb qhov chaw tuaj yeem hloov kho.

6. Rotary ntaus ntawv xaiv tau rau cylindrical annular khoom kho.

Daim ntawv thov

Nws yog tsim rau precision txhaj molding, casting, vuam pwm ua thiab lwm yam lag luam;Txhua yam txias alloy steel, siab alloy steel forging, suav nrog Nickel vuam cuab yeej steel, qib high-qib steel, tooj liab alloys, beryllium tooj liab, high-toughness aluminium thiab lwm yam khoom siv hlau.

Tsis muaj

| Qauv | BEC-MW 200 | BEC-MW 300 | BEC-MW 400 |

| Laser zog | 200 W | 300 W | 400 W |

| Laser wavelength | 1064nm ua | ||

| Max.Tib Pulse Zog | 80j ua | 100 J | 120 J |

| Hom Laser | ND: YOG | ||

| Laser Pulse zaus | 0.1-100Hz | ||

| Pulse Dav | 0.1-20ms | ||

| Vuam Qhov tob | 0.1-1.5 hli | 0.1-2 hli | 0.1-3 hli |

| Chaw ua haujlwm | X = 450mm, Y = 350mm (X, Y tuaj yeem hloov kho manually, Z-axis tuaj yeem nqa tau) | ||

| Kev soj ntsuam Systems | Microscope (optional monitoring system CCD duab kom loj) | ||

| Tswj System | Microcomputer program tswj | ||

| Kev siv fais fab | 6 kWm | 10 KW | 12 kWm |

| Txias System | Dej txias | ||

| Xav tau lub zog | 220V ± 10% / 380V ± 10% 50Hz lossis 60Hz | ||

| Packing Size & Nyhav | Tshuab: 144 * 66 * 127cm, Dej chiller: 87 * 65 * 146cm;Tag nrho qhov hnyav ntawm 450KG | ||

Cov qauv

Cov qauv

Paub meej