Nyob rau hauv xyoo tas los no, txoj kev loj hlob ntawm kev tsim khoom lag luam tau nrawm heev, thiab qhov kev thov rau kev ua hlau kuj tau nce ntxiv.Vuam yog ib qho ntawm cov txheej txheem tseem ceeb ntawm kev ua hlau, thiab cov txheej txheem vuam tsoos tsis tuaj yeem ua tau raws li qhov xav tau ntawm kev tsim khoom.Nyob rau hauv cov ntaub ntawv no, lubtes tuav laser welding tshuabtau yug los, uas tau txais kev qhuas dav heev thaum nws tau pib, thiab hloov pauv cov tsoos vuam nyias phaj vuam ua lag luam.

Covtes tuav fiber ntau laser vuam tshuabyog ib tiam tshiab ntawm cov khoom siv laser vuam.Nws belongs rau kev sib cuag welding.Nws tsis xav tau lub zog thaum lub sijhawm ua haujlwm., uas melts cov khoom nyob rau hauv, thiab ces txias thiab crystallizes tsim ib tug weld.

ib.Tsis muaj zog sab nraud yuav raug siv rau ntawm lub workpiece

Thaum lub tes tuav laser vuam tshuab ua cov txheej txheem, txij li nws yuav tsis tuaj rau hauv kev sib cuag nrog cov txheej txheem ua tiav, yuav tsis muaj kev ntxhov siab sab nraud ntawm cov txheej txheem ua tiav thaum tag nrho cov txheej txheem vuam, thiab lub zog concentration tsim los ntawm laser yog heev. siab.Lub thermal cuam tshuam ntawm ib puag ncig ntawm ib feem yog me me, yog li qhov yuav tsis deformed thaum vuam.

b.Vuam ntawm cov khoom sib txawv tuaj yeem pom tau

Nyob rau hauv cov txheej txheem welding ib txwm, feem ntau tsuas yog ob lub workpieces ua los ntawm cov khoom siv tib yam tuaj yeem welded, tab sis cov txheej txheem laser welding ntawm cov qib siab ntawm tes tuav laser vuam tshuab tsis tuaj yeem tsuas yog vuam siab melting point thiab ntau yam ntaub ntawv uas nyuaj rau yaj thiab vuam. , xws li titanium alloy, aluminium alloy thiab lwm yam ntaub ntawv.Tsis tas li ntawd, lub laser vuam ua tshuab kuj tuaj yeem paub qhov vuam ntawm qee cov ntaub ntawv sib txawv, tawg los ntawm kev txwv vuam ntawm cov ntaub ntawv.

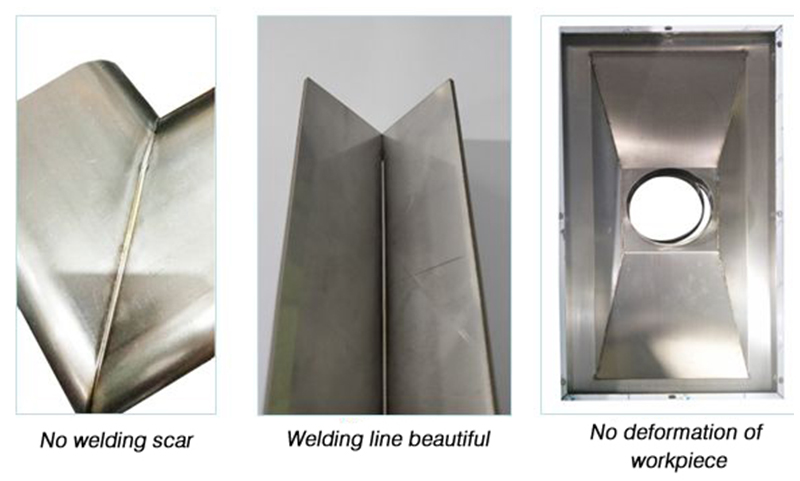

c.Nqaim vuam seam, zoo huv si thiab zoo nkauj tsos

Lub laser vuam tshuab ntawm tes tuav laser vuam tshuab yog siab heev, tsis tsuas yog tsis paug ib puag ncig, tab sis kuj tsim me me solder pob qij txha, nqaim vuam seams, uniform vuam seam qauv, tsawg pores thiab tsis xws luag, uas yuav txo tau thiab optimize cov niam txiv cov khoom impurities, Yog li ntawd, tom qab vuam, tsis tsuas yog ntau yam kev tiv thaiv yog zoo heev, tab sis cov nto ntawm cov khoom kuj zoo heev thiab zoo nkauj.

Nta ntawmtes tuav laser welding tshuab:

1. Cov cuab yeej yog me me

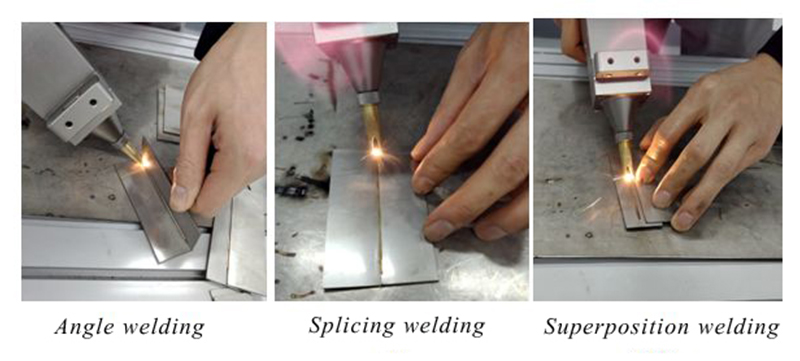

2. Kev ua haujlwm yooj yim thiab yooj yim, tuaj yeem paub qhov vuam sab nraud

3. Zoo beam zoo, ceev ceev, me me thermal deformation, precision thiab siab integration

4. Lub vuam seam yog zoo nkauj, tiaj tus thiab tsis muaj qhov hws, thiab tsis muaj kev kho lossis kev kho yooj yim yog yuav tsum tau tom qab vuam.

5. Lub tes tuav vuam phom tuaj yeem welding lub workpiece ntawm txhua lub kaum ntse ntse, uas yog tsim rau qhov chaw vuam ntawm txoj kev welds thiab ntau yam khoom siv.

Qhov zoo ntawm tes tuav laser vuam tshuab:

1. Kev ua haujlwm yog yooj yim thiab siv tau yooj yim: lub tes tuav laser vuam tshuab yog ib qho yooj yim rau kev khiav lag luam thiab muaj nqi zog tsawg.

2. Ceev ceev vuam ceev: Lub tes tuav laser vuam tshuab yog txuas txuas txuas, lub zog ntawm lub nqaj yog ntom, vuam siv tau zoo thiab kev kub ceev, qhov vuam qhov chaw me me, qhov chaw tshav kub yog me me, vuam seam yog du. thiab zoo nkauj, thiab cov txheej txheem sib tsoo tom qab raug txo.

3. Ntau yam khoom siv vuam: Lub tes tuav laser vuam tshuab tuaj yeem vuam cov khoom siv hlau xws li stainless hlau phaj, hlau phaj, galvanized phaj, thiab txhuas daim hlau.

4. Kev ua haujlwm tsawg ib puag ncig: Lub tes tuav laser vuam tshuab tsis xav tau lub rooj vuam tshwj xeeb, cov khoom siv nyob hauv ib qho chaw me me, thiab kev ua haujlwm yog hloov tau.Nws yog txawm peem rau nrog ob peb meters ntawm optical fiber extension kab, uas yuav tsum tau tsiv mus nyob rau hauv ntev-ntev kev khiav hauj lwm yam tsis muaj kev txwv ib puag ncig.

5. Kev ua haujlwm ruaj khov: Lub laser tau nruab nrog cov khoom siv dej txias, uas tuaj yeem ua kom muaj kev ua haujlwm siab ua haujlwm tsis tu ncua.

6. Kev ua haujlwm siab: Lub tes tuav laser vuam tshuab tuaj yeem tsis tsuas yog ua haujlwm vuam, tab sis kuj kho pwm.Lub neej ntawm lub laser yog 100,000 teev, uas yog ntev tshaj li qhov kev pab cuam lub neej ntawm cov cuab yeej zoo tib yam, thiab nws yog tus nqi-zoo.

Kev sib piv ntawm kev siv hluav taws xob nruab nrab ntawmtes tuav laser welding tshuabthiab argon arc vuam:

Piv nrog rau cov tsoos arc vuam, lub tes tuav laser vuam tshuab txuag tau li ntawm 80% mus rau 90% ntawm lub zog hluav taws xob, thiab cov nqi ua haujlwm yuav raug txo los ntawm 30%.Kev sib piv ntawm cov nyhuv vuam: tes tuav laser vuam tshuab tuaj yeem ua tiav cov hlau tsis sib xws thiab cov hlau tsis sib xws.Ceev ceev, me me deformation thiab me me tshav kub cuam tshuam cheeb tsam.Cov welds zoo nkauj, tiaj tus, thiab tsis muaj porosity.Tes tuav laser welder rau me me qhib qhov chaw thiab vuam.Kev sib piv cov txheej txheem tom qab: Lub tes tuav laser vuam tshuab muaj cov cua kub tsis tshua muaj kev tawm tswv yim thiab me me deformation ntawm lub workpiece thaum vuam, thiab tuaj yeem tau txais qhov vuam zoo nkauj yam tsis muaj lossis tsuas yog kev kho yooj yim (nyob ntawm qhov yuav tsum tau ua ntawm qhov vuam nto).Lub tes tuav laser vuam tshuab tuaj yeem txo tus nqi zog ntawm cov txheej txheem polishing loj thiab qib.

Daim ntawv thov teb ntawm tes tuav laser vuam tshuab:

Feem ntau yog rau txoj haujlwm ruaj khov ntawm cov ntawv loj thiab nruab nrab ntawm cov ntawv hlau, txee, chassis, aluminium alloy qhov rooj thiab qhov rais thav duab, stainless hlau ntxhua khaub ncaws thiab lwm yam haujlwm loj xws li lub kaum sab xis sab xis, sab xis sab xis, dav hlau vuam, me me tshav kub cuam tshuam. thaj tsam thaum lub sij hawm vuam, me me deformation, thiab vuam qhov tob loj thiab ruaj khov welded.Siv dav hauv kev lag luam hauv chav ua noj thiab chav dej, kev lag luam hauv tsev, kev lag luam tshaj tawm, kev lag luam pwm, stainless hlau khoom lag luam, stainless hlau engineering kev lag luam, qhov rooj thiab qhov rais kev lag luam, handicraft kev lag luam, khoom siv hauv tsev, kev lag luam rooj tog, kev lag luam pib, thiab lwm yam.

Daim ntawv thov thiab kev txawj ntse ntawmlaser vuam tshuabtau dhau los ua cov cuab yeej muaj zog hauv cov khoom siv hauv kev lag luam.Qhov kev ua tau zoo tshaj plaws thiab kev ua haujlwm zoo heev ntawm tes tuav laser vuam tshuab tau tsim muaj txiaj ntsig zoo rau kev tsim cov lag luam loj., kuj yog qhov kev xaiv ntawm ntau thiab ntau ua cov nroj tsuag.

Post lub sij hawm: May-10-2023