Laser vuam tshuabyog ib yam khoom siv vuam siv feem ntau siv hauv kev tsim khoom, thiab nws tseem yog lub tshuab tseem ceeb rau kev ua cov khoom siv laser.Laser vuam tshuab tau maj mam loj hlob los ntawm kev loj hlob thaum ntxov mus rau tam sim no, thiab ntau hom vuam tshuab tau muab los.

Laser vuam yog ib yam tshiab ntawm vuam txoj kev thiab ib qho tseem ceeb ntawm kev siv cov khoom siv technology.Laser welding feem ntau yog tsom rau kev vuam ntawm cov ntaub ntawv nyias-walled thiab precision qhov chaw.Cov txheej txheem welding belongs rau cov cua kub conduction hom, uas yog, qhov saum npoo ntawm lub workpiece yog rhuab los ntawm laser hluav taws xob, thiab qhov chaw tshav kub dhau los ntawm tshav kub conduction diffuses rau sab hauv, thiab lub workpiece yog melted los ntawm ib tug tshwj xeeb molten pas dej ua ke. tswj tsis tau xws li qhov dav, lub zog, lub zog siab tshaj plaws thiab rov ua dua zaus ntawm lub laser mem tes.Nws tuaj yeem paub qhov chaw vuam, taub qab vuam, plooj vuam, vuam vuam, thiab lwm yam. Cov vuam seam dav yog me me, qhov kub cuam tshuam cheeb tsam me me, qhov deformation me me, vuam ceev ceev, vuam seam yog du thiab zoo nkauj, thiab tsis muaj kev kho mob lossis kev kho yooj yim yog xav tau tom qab vuam.Lub vuam seam yog qhov zoo, tsis muaj qhov pores, tuaj yeem tswj tau qhov tseeb, muaj qhov chaw me me, thiab muaj qhov tseeb qhov chaw siab, thiab yooj yim rau automate.

Kev kho ntawm laser vuam tshuab:

Covlaser vuam tshuabxav tau kev saib xyuas, thiab qhov kub ntawm lub tank dej yuav tsum tau kho nyob rau lub caij ntuj no thiab lub caij ntuj sov.Tiv thaiv kom tsis txhob muaj cua sov hauv chav sov los yog kub dhau los cuam tshuam rau lub zog hluav taws xob laser.Nws raug nquahu kom kho qhov kub ntawm lub tank dej mus rau 3 ~ 5 degrees qis dua chav tsev kub raws li chav tsev kub, uas tuaj yeem tsis tsuas yog ua kom lub zog tso zis ntawm lub laser, tab sis kuj ua kom muaj kev ruaj ntseg ntawm cov zis laser.

1. Kev teeb tsa dej kub

Cov dej txias txias muaj qhov cuam tshuam ncaj qha rau ntawm electro-optical conversion efficiency, stability thiab condensation.Raws li ib txwm muaj, cov dej txias txias yog teem raws li hauv qab no: cov dej ntshiab (tseem hu ua dej tsis kub, siv los ua kom txias lub laser vuam tshuab module), cov dej kub ntawm cov dej hauv Circuit Court feem ntau yuav tsum tau teem rau ntawm li 21 ° C, thiab nws tuaj yeem tsim kom tsim nyog ntawm 20 txog 25 ° C raws li qhov xwm txheej.Kev kho.Qhov kev hloov kho no yuav tsum tau ua los ntawm tus kws tshaj lij.

Cov dej kub ntawm cov dej deionized DI (tseem hu ua dej kub, siv rau qhov chaw kho qhov muag txias) yuav tsum tau teem caij ntawm 27 ° C thiab 33 ° C.Qhov ntsuas kub no yuav tsum tau kho raws li qhov ntsuas kub thiab av noo.Qhov siab dua cov av noo, qhov siab dua cov dej kub ntawm DI dej yuav tsum tau nce raws li.Lub hauv paus ntsiab lus yog: DI dej kub yuav tsum siab tshaj qhov dej lwg taw tes.

2. Kev tiv thaiv kev tiv thaiv xws li cov khoom siv hluav taws xob sab hauv lossis kho qhov muag

Lub hom phiaj tseem ceeb yog los tiv thaiv condensation ntawm hluav taws xob lossis optical Cheebtsam hauv lublaser vuam tshuab.Xyuas kom meej tias lub chassis yog airtight: seb lub qhov rooj txee muaj nyob thiab raug kaw kom nruj;seb lub hoisting bolts sab saum toj yog nruj;seb qhov kev tiv thaiv npog ntawm qhov tsis siv kev sib txuas lus tswj interface nyob rau tom qab ntawm lub chassis yog them, thiab seb cov khoom siv puas raug kho.Khaws lub laser vuam tshuab rau thiab ua tib zoo mloog mus rau qhov sib lawv liag ntawm kev hloov ntawm thiab tawm.Nruab ib chav cua txias rau lub laser vuam tshuab, qhib lub tshuab cua txias dehumidification muaj nuj nqi thiab ua kom cov cua txias khiav tsis tu ncua thiab ruaj khov (suav nrog thaum hmo ntuj), kom qhov kub thiab av noo nyob rau hauv chav cua txias yog tswj ntawm 27 ° C thiab 50% feem.

3. Tshawb xyuas cov khoom siv kho qhov muag

Txhawm rau kom ntseeg tau tias lub laser ib txwm nyob rau hauv ib txwm ua haujlwm, tom qab ua haujlwm tas mus li lossis thaum nws raug tso tseg rau lub sijhawm, cov khoom siv hauv kev kho qhov muag xws li YAG pas nrig, dielectric diaphragm thiab lub lens tiv thaiv iav. yuav tsum tau kuaj xyuas ua ntej pib kom paub tseeb tias cov khoom siv kho qhov muag tsis muaj kuab paug., Yog tias muaj kev ua qias tuaj, nws yuav tsum tau hais txog lub sijhawm kom ntseeg tau tias txhua qhov kho qhov muag yuav tsis raug puas tsuaj nyob rau hauv lub zog laser irradiation.

4. Tshawb xyuas thiab kho lub laser resonator

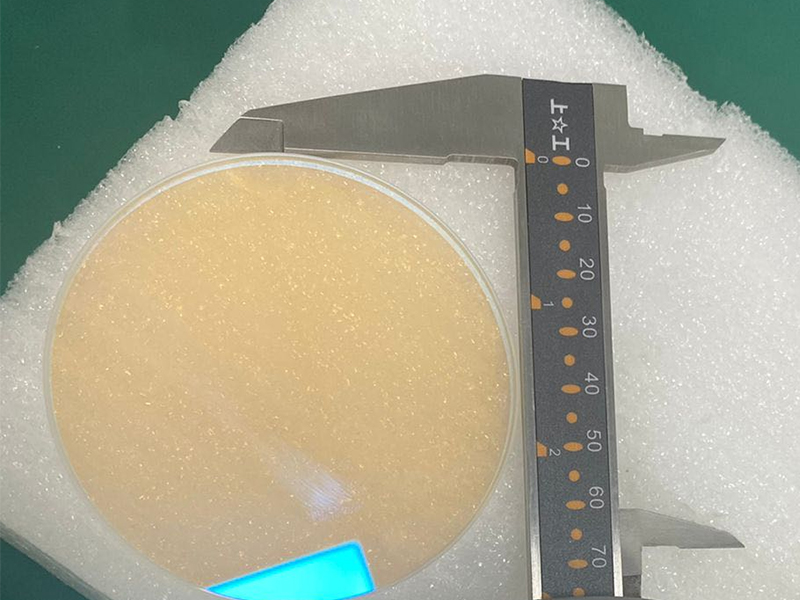

laser vuam tshuab cov tswv lag luam feem ntau tuaj yeem siv daim duab dub los xyuas qhov chaw tso zis laser.Thaum pom qhov chaw tsis sib xws lossis lub zog poob, lub resonator ntawm lub laser yuav tsum tau kho nyob rau hauv lub sij hawm los xyuas kom meej lub beam zoo ntawm laser tso zis.Cov neeg ua haujlwm debugging yuav tsum muaj kev nkag siab zoo ntawm kev tiv thaiv laser, thiab yuav tsum hnav tsom iav tshwj xeeb laser kev nyab xeeb thaum ua haujlwm.Kev hloov kho ntawm lub laser yuav tsum tau ua los ntawm cov neeg ua haujlwm tshwj xeeb uas tau txais kev cob qhia, txwv tsis pub lwm cov khoom ntawm txoj kev kho qhov muag yuav raug puas tsuaj vim qhov kev hloov pauv tsis zoo lossis kev hloov pauv ntawm lub laser.

5. Laser vuam tshuab ntxuav

Ua ntej thiab tom qab txhua txoj haujlwm, ua ntej ntxuav ib puag ncig kom cov av qhuav thiab huv si.Tom qab ntawd ua haujlwm zoo ntawm kev tu YAG laser welding tshuab cov cuab yeej, suav nrog cov txheej txheem ntawm lub chassis, kev soj ntsuam, thiab qhov chaw ua haujlwm, uas yuav tsum tsis txhob muaj cov khib nyiab thiab huv.Cov tsom iav tiv thaiv yuav tsum tau ua kom huv si.

Laser vuam tshuabyog dav siv nyob rau hauv kev ua cov hniav hniav nyiaj hniav kub, hniav nyiaj hniav kub vuam, silicon steel ntawv vuam, sensor vuam, roj teeb hau vuam thiab pwm vuam.

Post lub sij hawm: May-06-2023